via ScienceAlert

Titanium dioxide breaks down smog particles in the air, and students in the US have shown that in one year, one roof coated in it can break down the smog from a car that’s driven 17,000 km(10,500 miles). And every day, 21 tonnes of smog could be eliminated by one million treated roofs.

http://txchnologist.com/post/88500055810/students-show-common-compound-breaks-down-air-pollution

Kawai Tam, Chun-Yu “Jimmy” Liang, Jessica Moncayo, Edwin Rodriguez, Carlos Espinoza, Kelly McCoy, David Cocker and Louis Lancaster. From UC Riverside. Not just “Engineering students”.

This is important.

invention

/

“Until we discover matter to energy conversion, this might be the closest we can get.” - Microsoft Can Now Turn Any Space Into The Holodeck

/

The Samsung Smart Bike has rear view camera, and can create a bike lane for protection.

Looks like a tank though.

/

/

3d printing with sand using sunlight(!?)

/

google glasses. inevitable.

/

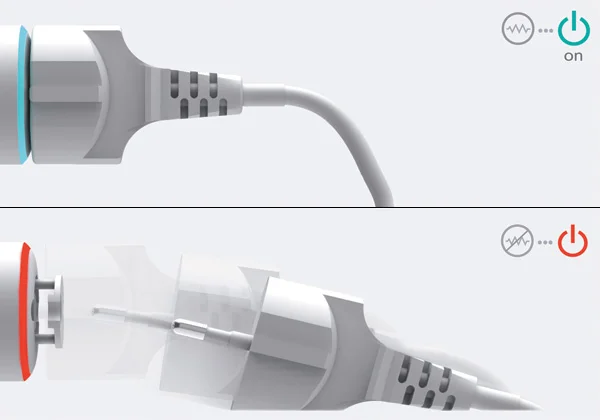

An energy-saving socket concept that’s not for the easily startled

The PumPing Tap is a spring-loaded electrical socket that physically ejects plugs belonging to appliances and electronics that are not being used but still drawing small amounts of energy in standby mode.

/

If Hoyoung Lee’s concept printer becomes reality, you’ll never throw away another pencil stub and never buy another ink cartridge. The pencil printer separates the wood from pencils and uses the lead to print documents. There’s even a built-in eraser component that allows you to remove text from a page and reuse the paper, so you’ll be saving money and trees.

15 bizarre — but cool — green inventions

/

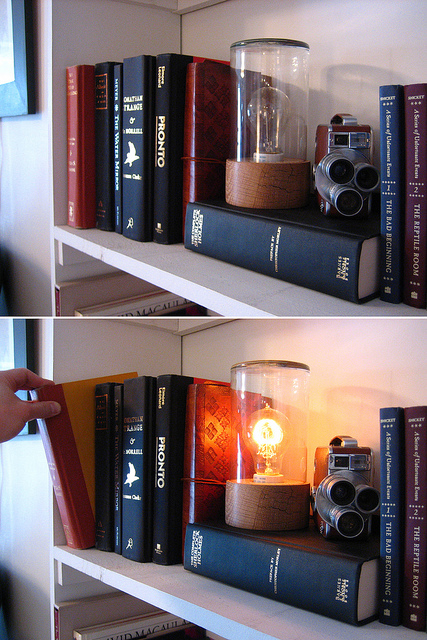

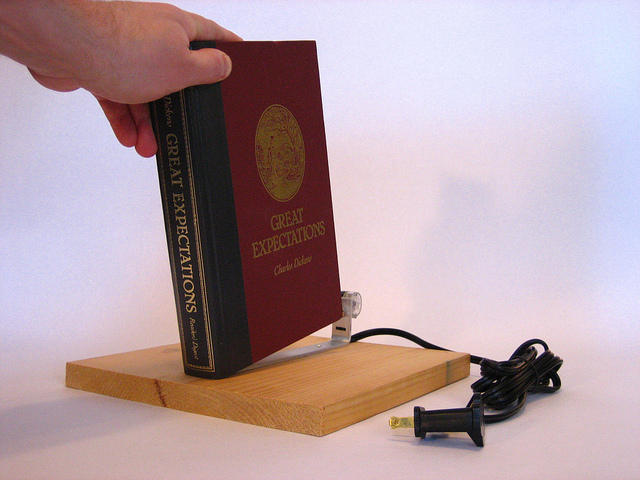

“Use to activate a secret passageway (or turn on a lamp). When placed in a bookshelf, this electrical switch uses your favorite hard-bound book, without damaging it, to conceal its true function. Lamp not included.”

/

Groasis Waterboxx. Grow plants anywhere through condensation.

/

/

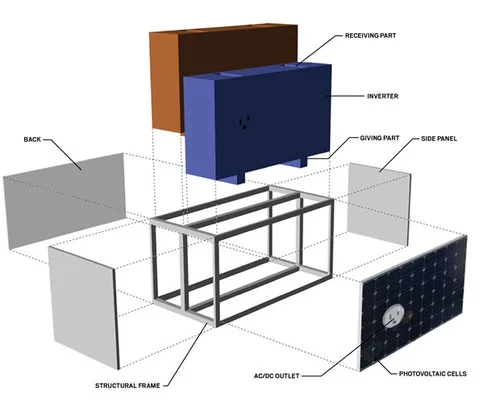

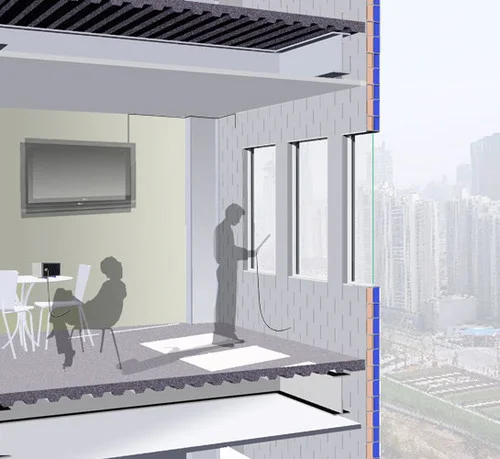

SOLAR MASONRY UNIT

Alexander Keller

Providence, Rhode Island

In an age of high-performance glass skins and pollution-eating concrete, it was only a matter of time before someone put the fusty old brick to work. Alexander Keller’s Solar Masonry Units convert the sun’s energy to electricity that can power laptops, washing machines, and even electric cars. “We are surrounded by brick surfaces and other building envelopes that have vast potential to be energy collectors,” says the 23-year-old graduate student at the Rhode Island School of Design. “Solar Masonry Units allow our cities to be built directly from the material that is powering our everyday processes.” Dotted with 32 or 128 PV cells, depending on size, the unit packs an inverter and a battery into a recycled plastic shell. Bricks bind together via interlocking male and female parts—no mortar needed—and strategically placed outlets let people plug in, whether they’re watching TV in their apartments or catching some fresh air, laptop in hand. “Walls of the city should replace power plants,” Keller says. “They should be alive and charged.” They should, as he tells it, lay “the foundation for the future of sustainability.”

http://www.metropolismag.com/nextgen/ng_story.php?article_id=4259

/

OCTA.BOT

Alexis Rochas

Los Angeles

Octa.Bot, a new universal building system from the Southern California Institute of Architecture professor Alexis Rochas, makes the traditional space frame look like a Rube Goldberg machine. Standard frames have fixed joints, which don’t allow for much design variation. Octa.Bot has lock-in-place swivel joints that free up connecting struts to take on nearly any shape at all. Instead of designing boring old bridges, architects can whip up complex pavilions, houses, and landscapes. What’s more, Rochas, 35, says, the system trims a structure’s mass by as much as 60 percent and slashes construction time in half, compared with conventional methods. “The Octa.Bot fitting greatly simplifies execution of complex assemblies by reducing the amount of geometrical information necessary,” he says. Three case studies of Octa.Bot were recently featured in an exhibit at SCI-Arc; a fourth will show this summer at the first Biennial of the Americas, in Denver. After that? “Octa.Bot,” Rochas says, “for everyone.”

http://www.metropolismag.com/nextgen/ng_story.php?article_id=4259

/

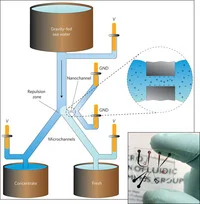

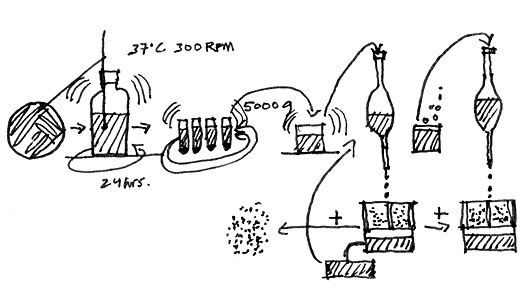

“An American architecture professor, Ginger Krieg Dosier, 32, Assistant Professor of Architecture at American University of Sharjah (AUS) in Abu Dhabi, has won this year’s prestigious Metropolis Next Generation Design Prize for “Biomanufactured Brick.” The 2010 Next Generation Prize Challenge was “ONE DESIGN FIX FOR THE FUTURE” - a small fix to change the world. The Next Generation judges decided that Professor Dosier’s well-documented and -tested plan to replace clay-fired brick with a brick made with bacteria and sand, met the challenge perfectly.

There are over 1.3 trillion bricks manufactured each year worldwide, and over 10% are made by hand in coal-fired ovens. On average, the baking process emits 1.4 pounds of carbon per brick - more than the world’s entire aviation fleet. In countries like India and China, outdated coal-fired brick kilns consume more energy, emit more carbon, and produce great quantities of particulate air pollution. Dosier’s process replaces baking with simple mixing, and because it is low-tech (apart from the production of the bacterial activate), can be done onsite in localities without modern infrastructure. The process uses no heat at all:mixing sand and non-pathogenic bacteria (sporosar) and putting the mixture into molds. The bacteria induce calcite precipitation in the sand and yield bricks with sandstone-like properties. If biomanufactured bricks replaced each new brick on the planet, it would save nearly 800 million tons of CO2 annually.

1-2-3 brick-making with Dosier’s competition-winning concept: pour the bacteria solution together with the cementing solution over the sand inside the formwork, let it saturate and harden (currently about one week) - voilà: we have an ecobrick!

Bacteria is dunked in a broth of growth media. The solution then incubates in test tubes at 37˚C before it’s fed into sand-filled formwork via drip.”

/

/

Omega Hydroponic Garden Gets Five Times As Much Food Per Watt : TreeHugger

“We often wonder about the benefits of indoor hydroponic gardening, given that the sun is free. After all, Illegal hydroponic installations are often discovered by their abnormally high electricity use. Can Omega Garden system make high tech urban gardening economically feasible and actually more energy efficient than growing outdoors?

Vancouver based Omega Garden’s Carousel system rotates the plants around the bulb. They claim that it yields three to five times the weight of plant per watt of electricity used, compared to conventional flat systems. Their commercial carousel system produces as much as a 1500 square foot greenhouse in only 150 square feet, and their LED system just sips electricity.”

/

/

Somebody Please Make the Rambler Socket

This is one of the best power socket ideas I’ve seen in a long while: A socket with an extension cord inside the wall itself. They should make these standard everywhere. I even like the name: The Rambler Socket.It works easily: Pinch the sockets sides, pull it out, and use with your electrical thingamajig. Once your are done, tug the wire gently, and let the recoil mechanism neatly store away the extension cable. Power socket people of the world: Make it happen. [via]

Want.

/

(via jauderho)